Frequently Asked Questions

Q1. How does it work?

The condensation removal procedure is relatively straightforward, vents are fitted to the unit to allow air to enter and expel from the unit when needed, and the venting system prevents any further damage to the unit’s seals.

By allowing air to flow through the unit, the trapped water in the air space will turn to vapour as the temperature rises and will be expelled from the unit through the top vent, the air that replaces the vapour as the temperature drops will contain significantly less moisture.

The moisture in the air is prevented from fogging or condensing on the glass by the special anti-fog coating that we apply to the internal glass surface.

Finally the units bottom section is resealed from inside the unit using a special sealer that turns the trapped moisture in the bottom spacer bar into a solid, and also prevents any moisture entering the unit from the bottom rebate should there be a problem with the drainage system or seals on the frame.

The failed unit is now re-classified as a pressure equalised unit and will not react to temperature changes.

Q2. Can Marks or Stains Be Removed

Condensation inside double glazing can permanently damage the glass.

The components used to make a sealed unit quickly start to breakdown when exposed to moisture on a daily basis, the constant evaporation and condensing of the water on the glass quickly starts to leave deposits on the glass, if left for a long time they will become baked on the glass in the summer months, these deposits are virtually impossible to remove.

The defogging of sealed units removes the moisture contained within the unit and cleans the glass, it will not however remove stains or streaks inside the unit that are baked on or are leaching from the glass.

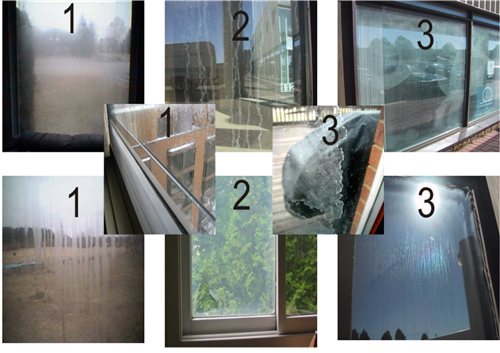

Stage one damage as highlighted in the above picture can be removed this includes, fog, mist and water.

Stage two damage as highlighted in the above picture can sometimes be removed, or significantly reduced. After the process is carried out the damage will not get any worse. many customers will accept a certain amount of marking if the cost of replacing the unit is very high or if the unit is in a location that is not used on a daily basis such as a spare bedroom etc.

Stage three damage as highlighted in the above picture can not be removed.

Q3. Can it be done from the inside?

The simple answer is yes (as long as the unit is not made of toughened glass).

Many units are fitted above extensions and areas where it is difficult to get access to the external glass pane, using additional vents and tools (included in the advanced kit only) it is possible to drill the outside pane of glass from the inside of the building, a special vent is then inserted into the hole.

For further details on the procedure and the equipment needed contact our technical help line on 01335 348807

Q4. My units are gas filled?

All units are gas filled air is a mixture of mainly Nitrogen and Oxygen, some sealed units have Argon or Krypton gas installed, these heavier gases help with the units thermal performance

However as the seal has failed the heavier gases have long escaped and been replaced with moist air,

You could consider replacing the unit with a new heavy gas filled unit that will fail again in another 5 - 10 years.

Any money you might save by the slightly better thermal performance of heavy gas filled units will never pay for new units every few years.

Q5. How long does it take to work?

This is probably the most difficult question to answer, the truth is we do not know.

Having re-engineered thousands of units it is still impossible to estimate how long a unit will take to vent all the surplus moisture out of the unit.

The factors that affect how long it will take are:

1. How much water is trapped in the unit.

2. How big the unit is.

3. How wide the cavity is.

4. The time of the year.

5. The geographical position of the unit.

6. Exposure to solar radiation (suns rays).

7. Temperature of internal room.

All of these factors have to be taken into account, what we do know is that some units clear straight away, some units take a few days, and other units take weeks. If the unit has not cleared in 12 Weeks there is usually a problem with the spacer bar sealer.

If you follow our manual carefully a 99% success rate can easily be achieved, in a very few rare cases the spacer bar sealer will not seal the bottom of the unit on its first application, topping up the sealer is all that is normally required to clear the 1% of units that try to resist being re-engineered.

Q6. I have heard it doesn't work?

It has taken over twenty years to perfect this process and only in recent years has the success rate reached 99-100%, many units over the years have failed to repair due to numerous reasons that are all basically associated to the condition of the window frame, if there was any problem whatsoever with the frames seals or drainage system the process would fail. Since the introduction of the Anti-Fog Coating and Spacer Bar Sealer 100% success rates are achievable.

In the UK many Housing Associations and Corporations now use this as their preferred method of dealing with failed units.